Mechanical, hydropneumatic and hydraulic modular vices for milling machines and machining centers, grinding vices

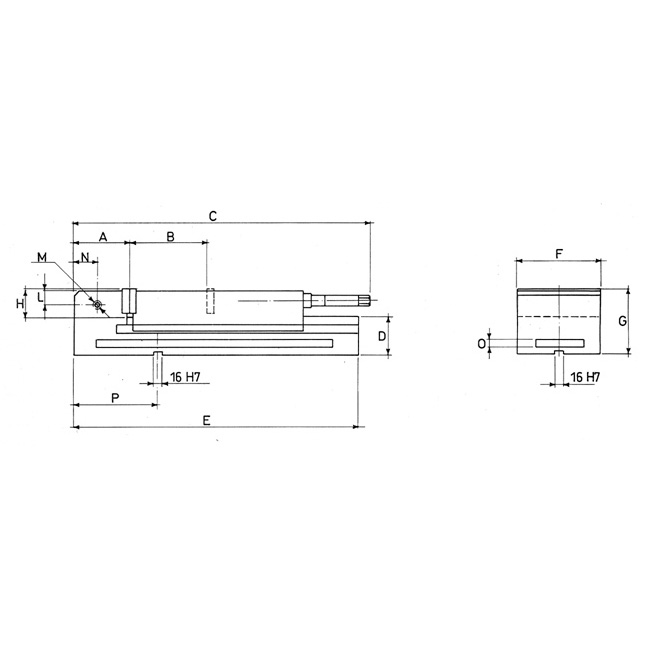

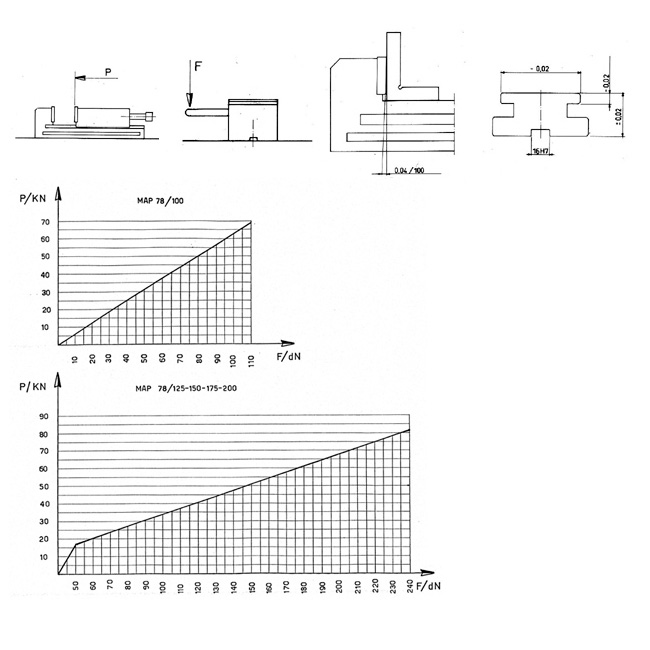

MAP/78-N MECHANICAL VICE

BREAKING LOAD Rmin = 61

ELONGATION %: A% = 3

Brinell Hardness: HB = 190-270

BREAKING LOAD Rmin = 61

ELONGATION %: A% = 3

ELONGATION %: A% = 3

BREAKING LOAD Rmin = 61

Brinell Hardness: HB = 190-270

ELONGATION %: A% = 3

BREAKING LOAD Rmin = 61

Brinell Hardness: HB = 190-270

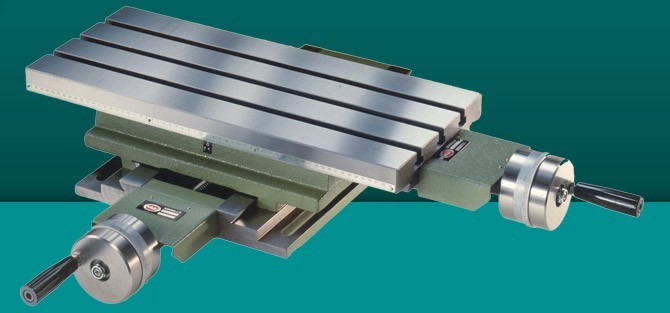

This vice has an extremely steady and compact structure devised to take the great stress of heavy milling work. This characteristic ensures no vibrations, safe clamping, high precision and well finished workpieces.

The position of the moving parts is accurate even with maximum opening thanks to tenon guides coupled to the base for very accurate working tolerances.

Since the lead screw, slideways and upper face are always protected from machining dust and chips, the vice is practically maintenance-free.

The vice can be supplied with a 360° graduated revolving base or without base; in the latter case the perfect alignment of the jaw is secured by two longitudinal and transversal grooves on the lower section.

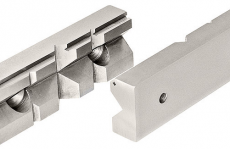

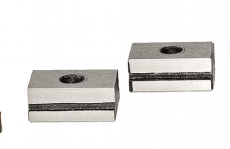

This model is fitted with fully ground flat jaws made of casehardened, tempered steel. Prismatic jaws to clamp cylindrical pieces are available on request.