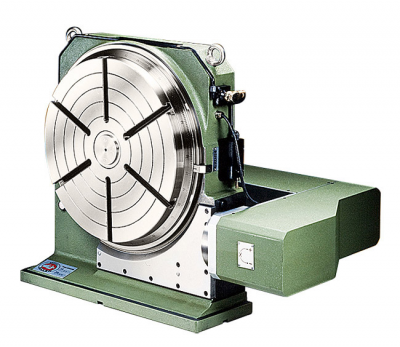

Automatic dividing tables

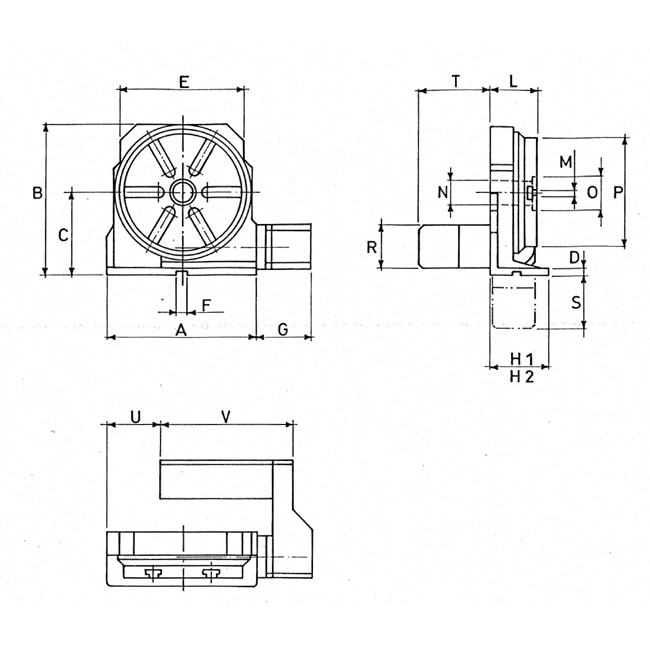

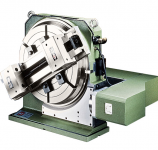

TDVO AUTOMATIC HORIZONTAL VERTICAL DIVIDING TABLE

BREAKING LOAD: Rmin = 26

ELONGATION %: A% = 26

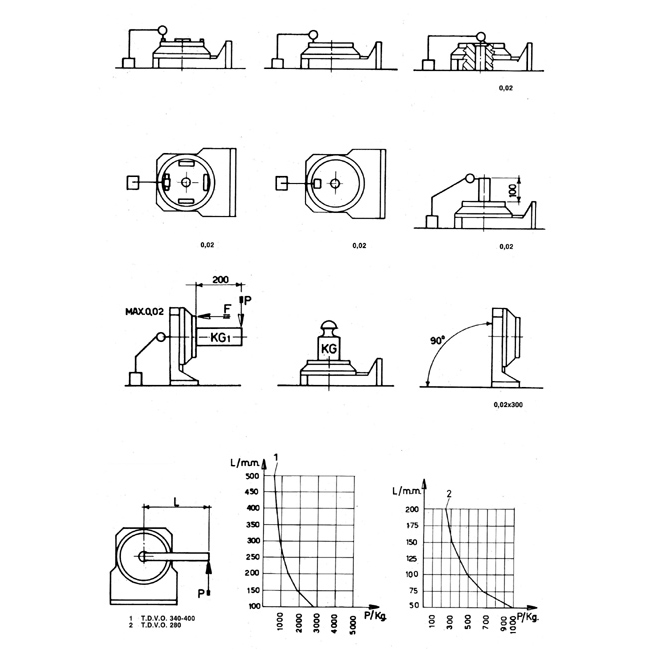

This dividing table has been specially designed to be positioned vertically but can also be positioned horizontally. Its compact and sturdy structure guarantees its stiffness and lack of vibrations during machining, which is indispensable to achieve high precision. The inner couplings are obtained by lapping the surfaces while the upper face and right-angled surfaces are properly ground. Transmission is given by the ring-gear and the worm, both completely immersed in an oil bath. The worm is made of UNI18 NiCrMo5 casehardened, tempered, ground steel; it is mounted on double-acting radial thrust ball bearings and can be adjusted axially. The clearance between the worm and the ring-gear can be adjusted radially. A spigot on the rotary table ensures the perfect centering of the rotation axis in relation to the axis of the machine tool. The motor unit is made up of a brushless motor connected to the worm of the table though a belt and toothed pulleys. An incremental encoder installed on the worm is a rotary transducer with a high number of impulses per revolution that detects the table position with an angular resolution of 0.001 degrees. The electronic equipment starts the air/oil pressure intensifier which, in turn, operates two hydraulic locking systems ensuring the accurate position achieved despite great stress during mechanical machining. A sensor inside the table identifies the mechanical zero setting of the rotating surface in order to always have a unique and unambiguous origin of reference. In addition to the divided positioning, the table is also suitable for rotary motion during milling; the rotation speed can be selected and adjusted using the potentiometer with which the table is fitted. All available inputs and outputs are wired to a connector and gathered in a slant top console which also houses the control unit, operating unit, relay logic and air/oil pressure intensifier of the hydraulic locking systems. Control is achieved by a numerical control unit or positioner that can be easily programmed and comes in different configurations and models in order to meet various user requirements. The table is also supplied with an interface that connects the dividing table with the machine tool - whether it is a conventional machine or a CNC machining centre - and allows its use in an automated work cycle. For further explanations and technical details on the operation of this device, please contact our customers' service. The table comes with an exhaustive instruction and service manual.