A high precision right-angled table specially devised to automatically position the pieces to drill or thread but also suitable for milling or contouring with conventional milling machines or other machine tools.

Its sturdy and compact structure can easily tolerate even the greatest stress caused by machining.

The adjustable, prismatic slideways are properly ground and coated with Turcite B anti-friction material which reduces friction thus increasing traverse speed even with heavy loads.

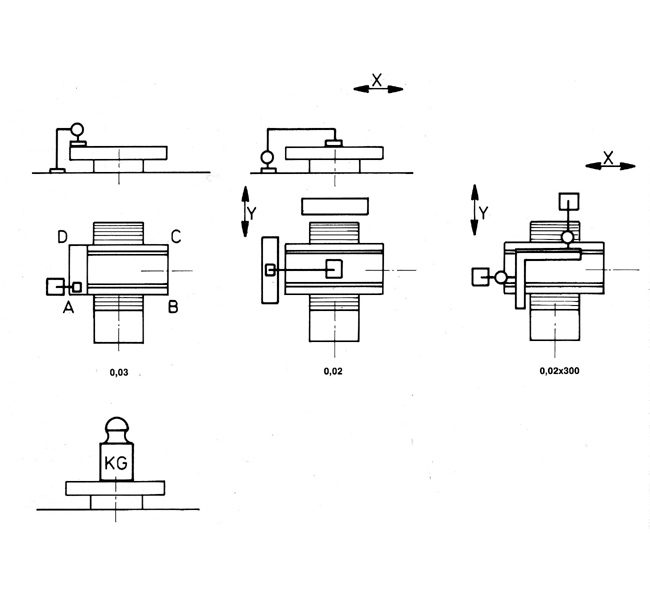

The steel ball screws have a 25 mm diameter and a 5 mm pitch. The threading is properly ground; the nuts are preloaded. The brushless motors are connected to the ball screws. The positioning of the axes is detected by optical transducers measuring in hundredths.

A motor pump unit with timer provides the pressure lubrication of all moving parts.

The maximum traversing speed is 10 metres per minute.

Specially devised protections made of painted sheets and hot-welded bellows, protect the slideways and the ball screws.

The electronic controls are wired in a slant top console.

This console also contains the operating controls with the transformer, the inductances, the CNC control unit which available in different configurations.

Other special coordinate table-machine tool combinations can be studied by our technical office which is entirely at your disposal for further explanations and technical details on the operation of this device.

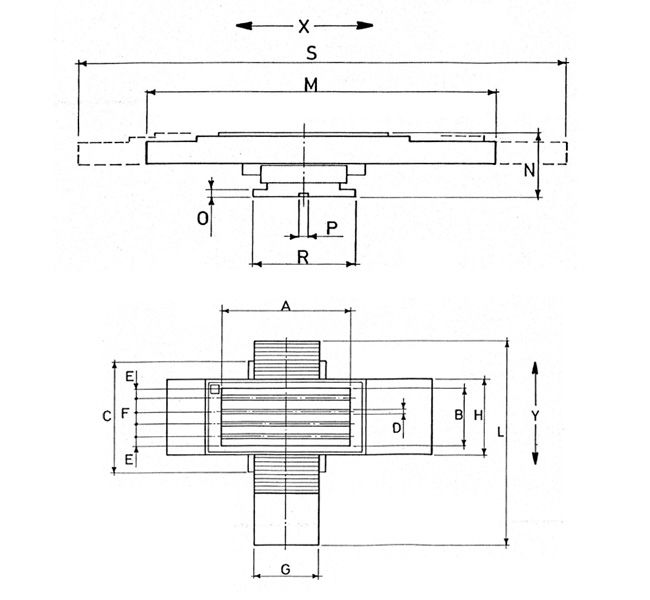

Technical data

Material: G26 cast iron UNI 5007

Breacking load Rmin = 26

Elongation %: A% = 1

Brinell hardness: HB = 190÷240

| TYPE | 400 | 500 | 600 |

|---|---|---|---|

| A | 575 | 675 | 775 |

| B | 280 | 320 | 370 |

| C | 505 | 605 | 705 |

| D | 14H7 | 14H7 | 14H7 |

| E | 53 | 55 | 65 |

| F | 58 | 70 | 80 |

| G | 340 | 362 | 422 |

| H | 382 | 422 | 472 |

| L | 1035 | 1145 | 1360 |

| M | 1150 | 1126 | 1485 |

| N | 220 | 220 | 220 |

| O | 24 | 24 | 24 |

| P | 16H7 | 16H7 | 16H7 |

| R | 385 | 400 | 460 |

| S | 1550 | 1686 | 2085 |

| X* | 400 | 460 | 600 |

| Y** | 360 | 360 | 470 |

| WEIGHT KG | 170 | 205 | 270 |

Note: Features and dimensions are subject to change.

*longitudinal stroke

**transversal stroke

Related products

Request information

"*" indicates required fields