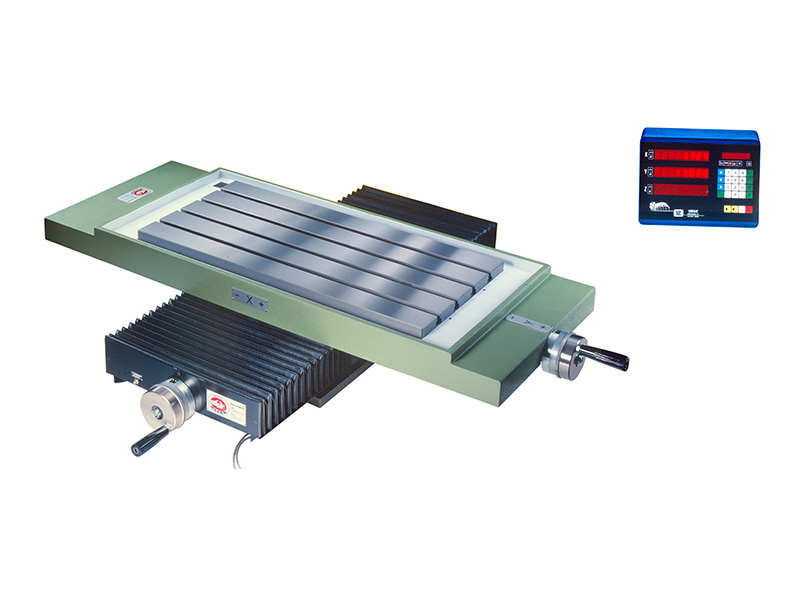

This table is constructed like a proper machine tool.

The faces are properly ground as are the adjustable prismatic slideways which are coated with Turcite B anti-friction material which reduces friction even when the upper splined surface carries heavy loads. The lead ball screws which have a 25 mm diameter and a 5 mm pitch, are made of steel, ground and mounted on radial thrust bearings that can be adjusted axially.

The preloaded nuts ensure stiffness and no clearance.

A manual lubrication system ensures the pressure lubrication of all moving parts from one delivery point.

Painted sheet and hot-welded bellows protect the slideways as well as the ball screws and allow the operator to work with a coolant without it overflowing from the upper splined table.

The table can be supplied with a digital measuring system that displays the axis position.

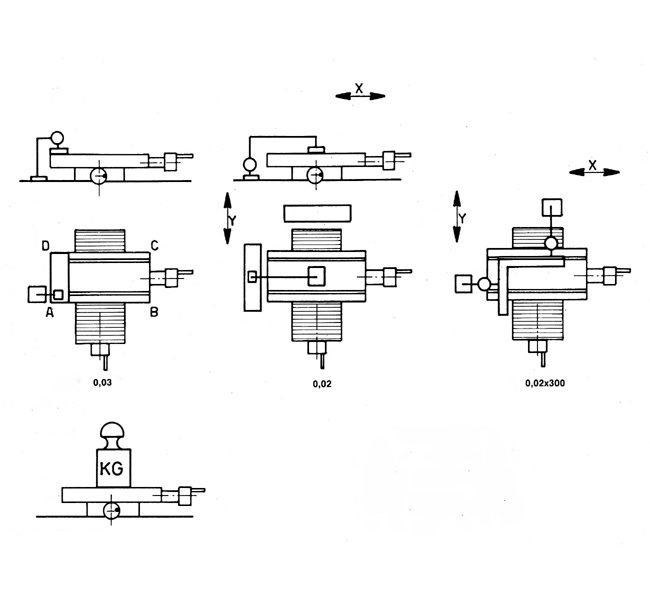

Other special applications of the table can be studied by our technical office which is entirely at your disposal for further technical details on the operation of this device.

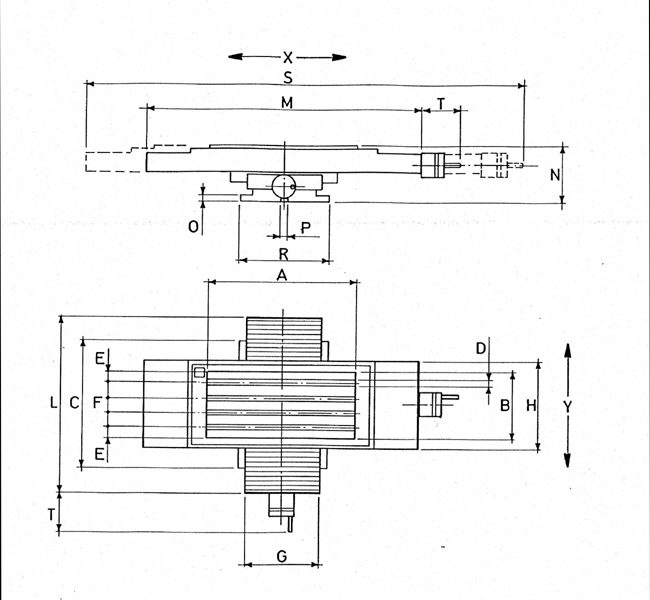

| TYPE | 400 | 500 | 600 |

|---|---|---|---|

| A | 575 | 675 | 775 |

| B | 280 | 320 | 370 |

| C | 505 | 605 | 705 |

| D | 14H7 | 14H7 | 14H7 |

| E | 53 | 55 | 65 |

| F | 58 | 70 | 80 |

| G | 340 | 362 | 422 |

| H | 382 | 422 | 472 |

| L | 708 | 845 | 1058 |

| M | 900 | 1045 | 1263 |

| N | 220 | 220 | 220 |

| O | 24 | 24 | 24 |

| P | 16H7 | 16H7 | 16H7 |

| R | 385 | 400 | 460 |

| S | 1500 | 1725 | 2063 |

| T | 160 | 160 | 160 |

| X* | 440 | 520 | 640 |

| Y** | 340 | 420 | 540 |

| WEIGHT KG | 150 | 180 | 250 |

Note: Features and dimensions are subject to change.

*longitudinal stroke

**transversal stroke

Related products

Request information

"*" indicates required fields