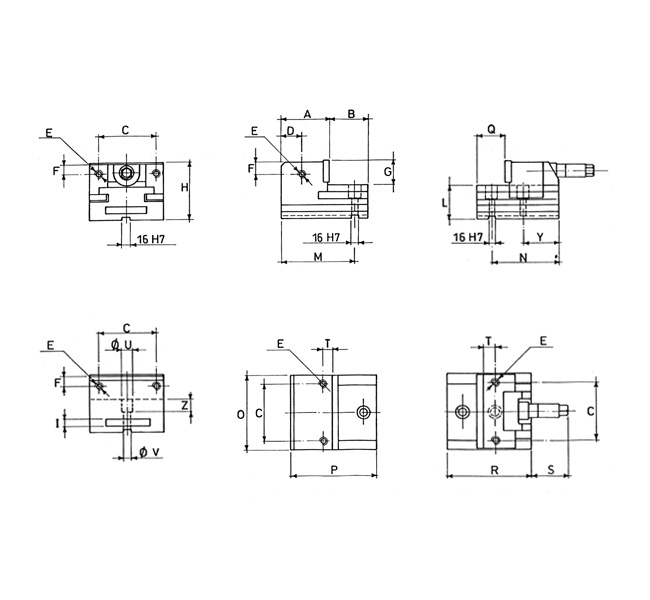

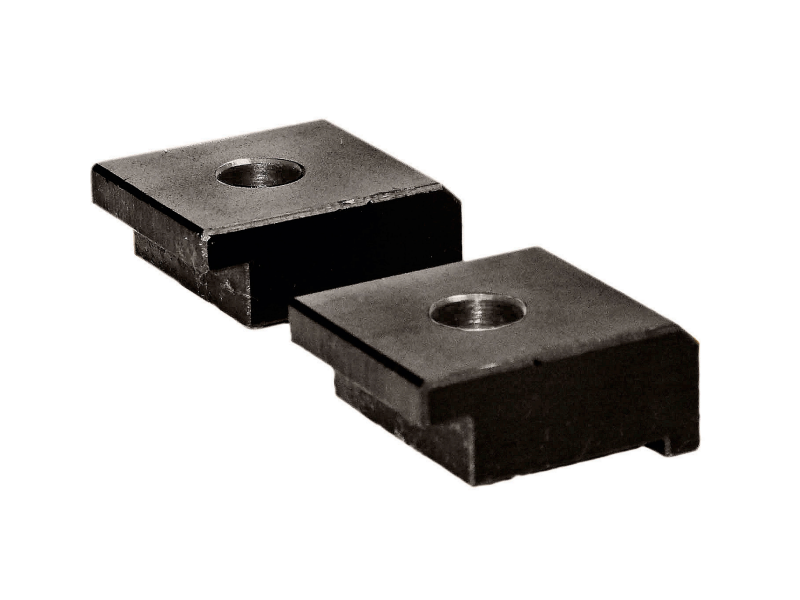

They are composed of the two main parts of the vice, i.e. the fixed head and the moving jaw. They have the same size and features of the MU/90 and are made of the same material which is GS 600 nodular cast iron.

They replace a complete vice when large openings are needed in order to clamp large pieces or to clamp a workpiece on different sides (see drawings).

The clamp parts can be fixed using side brackets or a series of holes set lengthwise. Thanks to their linear geometric shape, several clamp parts can be used aligned and side by side on the same table.

The alignment of the moving jaw and the fixed head is obtained by a longitudinal groove on the base.

| TYPE | 100 | 125 | 150 | 175 | 200 | TOLL. |

|---|---|---|---|---|---|---|

| A | 74.5 | 76.5 | 86.5 | 96.5 | 106.5 | |

| B | 75.5 | 63.5 | 63.5 | 3.5 | 63.5 | |

| C | 80 | 100 | 110 | 135 | 160 | |

| D | 30 | 32.5 | 37.5 | 45 | 50 | |

| E | M10 | M10 | M10 | M10 | M10 | |

| F | 25 | 25 | 25 | 25 | 25 | |

| G | 47 | 52 | 52 | 57 | 57 | |

| H | 102 | 112 | 112 | 127 | 127 | |

| I | 10 | 10 | 10 | 10 | 10 | |

| L | 55 | 60 | 60 | 70 | 70 | ±0.02 |

| M | 100 | 110 | 120 | 130 | 140 | ±0.05 |

| N | 145 | 220 | 200 | 205 | 205 | ±0.05 |

| O | 100 | 125 | 150 | 175 | 200 | |

| P | 150 | 150 | 170 | 180 | 190 | ±1.00 |

| Q | 77.5 | 100 | 100 | 100 | 100 | |

| R | 195 | 240 | 240 | 240 | 240 | ±1.00 |

| S | 90 | 92 | 92 | 87 | 87 | |

| T | 25 | 25 | 25 | 25 | 25 | |

| U | ø22 | ø22 | ø22 | ø22 | ø22 | |

| V | ø16 | ø16 | ø16 | ø16 | ø16 | |

| Z | 32 | 32 | 32 | 32 | 32 | |

| Y | 145 | 120 | 100 | 105 | 105 | |

| Fixed block weight. Kg | 8 | 11 | 15 | 21 | 26 | |

| Moving block weight. kg | 11 | 16 | 20 | 28 | 33 |

Note: Features and dimensions are subject to change.

Related products

Request information

"*" indicates required fields