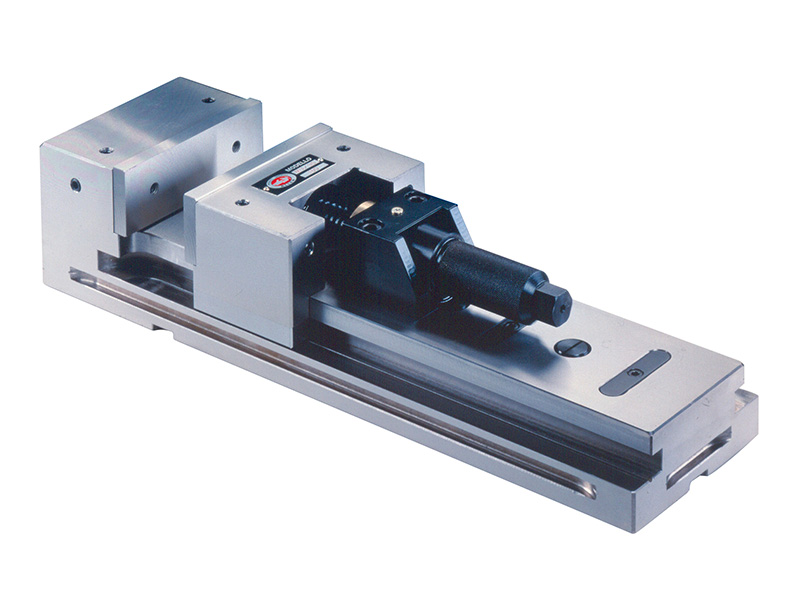

This vice is designed to meet the requirements of modern high efficiency machine tools and CNC machining centres. To this end MU/90 is made of vibration absorbing material, since vibrations have always been the cause of damage to both the workpieces and the machine tools.

Other important features of this vice are: quick assembly and alignment of the vice on the machine tool, large opening while maintaining small overall dimensions, versatile positioning, high clamping force and high precision. These features make this a very versatile vice.

The base and fixed jaw cast in one piece and the slideways are made of GS 600 nodular cast iron, a material well-known for its excellent mechanical features which make the vice very compact and steady even

when subjected to great stress. The moving parts slide on tenon guides which are machined with very

accurate tolerances.

All lower, upper and lateral faces are properly ground.

The vice has, therefore, a high degree of geometric precision and modularity so that it can be used vertically, horizontally or on its side, it can be mounted on cubes, right-angled supports or perfectly aligned with other vices. To this effect the vice is equipped with longitudinal and transversal alignment grooves; or can be fitted to the bench or equipment with side clamping brackets or through a series of central holes set lengthwise.

Another important feature is the piece clamping system which is ensured by a trapezoidal, left handed thread screw made of steel and coupled to a bronze lead screw with high mechanical resistance, so that high clamping force can be achieved. The screw / lead screw unit can be easily re-positioned in order to obtain the selected vice opening and clamp the piece under

the best mechanical conditions.

Removable protections ensure that the holes and the central joints for the lead screw support are free from

chips and dust. The assembly and disassembly of the screw, slideways and lead screw for cleaning and maintenance are extremely easy independently from the vice position.

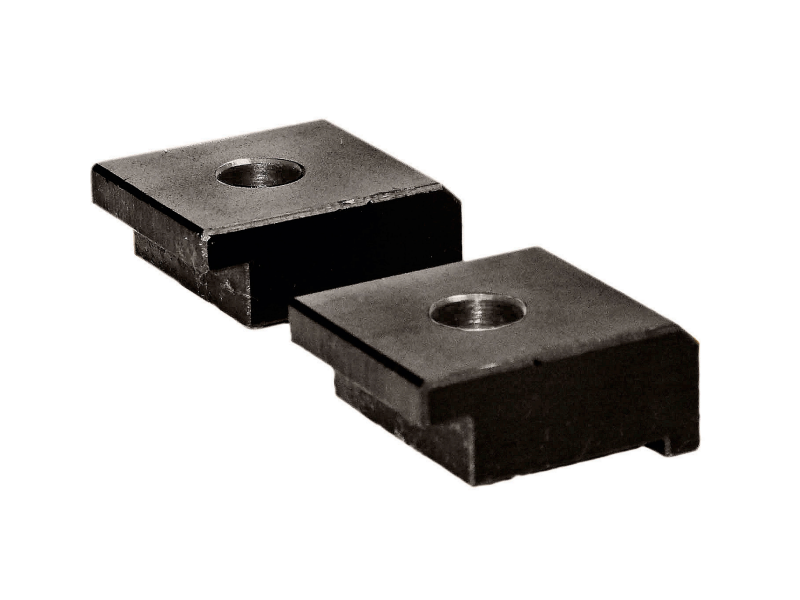

This model is fitted with ground flat jaws made of casehardened and tempered steel. Prismatic jaws to clamp cylindrical pieces are available on request. The vice can be supplied with a 360° graduated revolving base. The vice comes with a universal spanner for the removal of protections and of the lead screw support, the reversible ratchet spanner for piece clamping and 4 clamping brackets.

Technical data

Material: Cast iron GS 600-3 UNI 4544

Breaking load: Rmin = 61

Elongation %: A% = 3

Brinnel hardness: HB = 190÷270

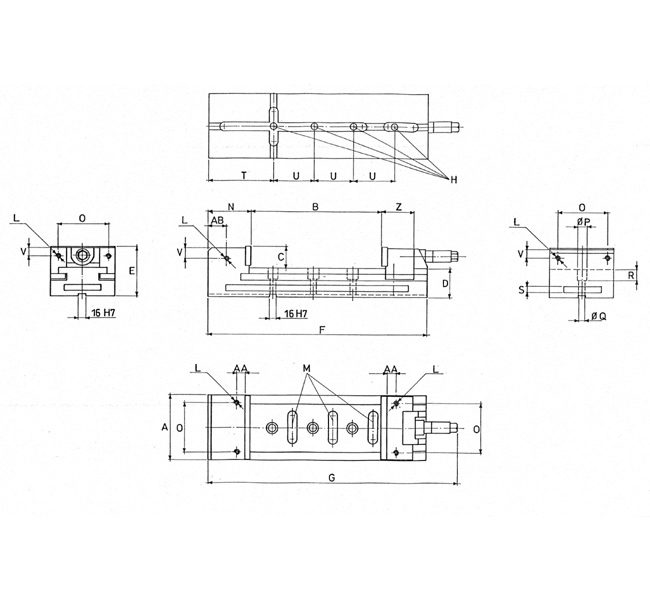

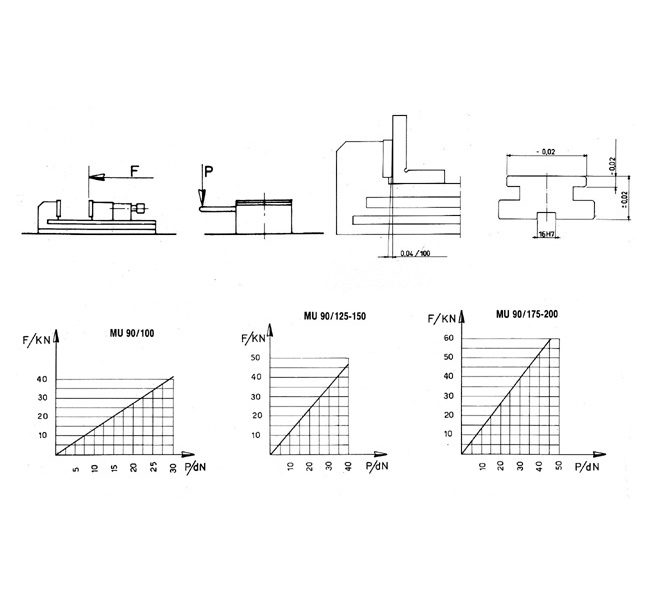

| TYPE | 100 | 125 | 150 | 175 | 200 | TOLL. |

|---|---|---|---|---|---|---|

| A | 100 | 125 | 150 | 175 | 200 | |

| B | 150 | 220 | 300 | 300/400 | 300/400/500 | +3.00/+5.00 |

| C | 47 | 52 | 52 | 57 | 57 | |

| D | 55 | 60 | 60 | 70 | 70 | ±0,02 |

| E | 102 | 112 | 112 | 127 | 127 | |

| F | 345 | 430 | 520 | 535/635 | 545/645/745 | ±0,1 |

| G | 435 | 522 | 612 | 622/722 | 632/732/832 | |

| H | 2 | 3 | 4 | 4/5 | 4/5/6 | |

| L | M10 | M10 | M10 | M10 | M10 | |

| M | 2 | 2 | 3 | 3/4 | 3/4/5 | |

| N | 74.5 | 76.5 | 86.5 | 96.5 | 106.5 | |

| O | 80 | 100 | 110 | 135 | 160 | |

| P | ø22 | ø22 | ø22 | ø22 | ø22 | |

| Q | ø16 | ø16 | ø16 | ø16 | ø16 | |

| R | 32 | 32 | 32 | 32 | 32 | |

| S | 10 | 10 | 10 | 10 | 10 | |

| T | 100 | 110 | 120 | 130 | 140 | ±0,05 |

| U | 100 | 100 | 100 | 100 | 100 | ±0,1 |

| V | 25 | 25 | 25 | 25 | 25 | |

| Z | 84.5 | 96.5 | 96.5 | 96.5 | 96.5 | |

| AA | 25 | 25 | 25 | 25 | 25 | |

| AB | 30 | 32.5 | 37.5 | 45 | 50 | |

| WEIGHT KG | 18 | 27 | 38 | 53/62 | 66/76/88 |

Note: Features and dimensions are subject to change.

Related products

Request information

"*" indicates required fields