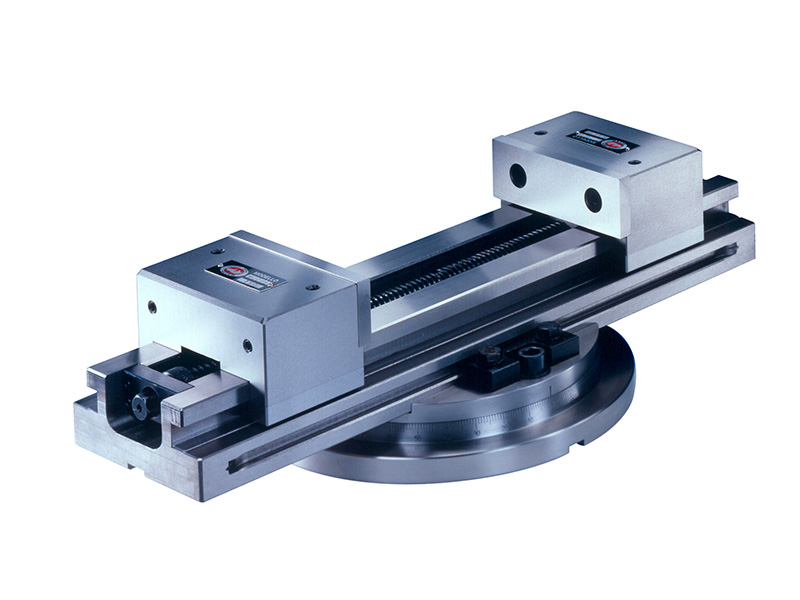

Morsa costruita in ghisa sferoidale GS 600 ad alta resistenza meccanica. La caratteristica principale di questa morsa è la chiusura concentrica delle due ganasce mobili, che permette il centraggio del pezzo da lavorare rispetto al centro della morsa.

L’alta precisione geometrica con cui la morsa è realizzata, la forma essenziale, la considerevole apertura e la praticità d’uso danno inoltre a questa morsa quella caratteristica di modularità nel comporre o nel trovare inserimento nelle attrezzature impiegate sulle moderne macchine utensili e centri di lavoro CNC.

La morsa si presta, infatti, ad essere piazzata oltre che orizzontalmente, anche verticalmente o sul suo fianco, montata su cubi e squadre, oppure in quelle attrezzature che richiedono l’impiego di più morse affiancate e allineate. La morsa può essere fornita completa di base girevole e graduata in 360°.

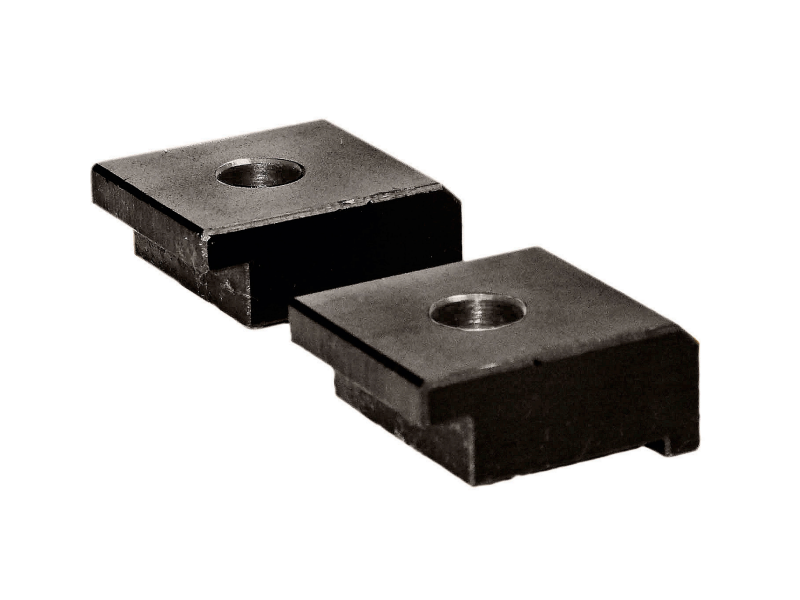

Le ganasce piane riportate sono in acciaio, cementate, temprate ed interamente rettificate. A richiesta vengono fornite le ganasce prismatiche, utilizzabili per il serraggio di pezzi cilindrici. Accessori in dotazione sono le 4 staffe di bloccaggio e la chiave a cricchetto reversibile usata per il serraggio del pezzo.

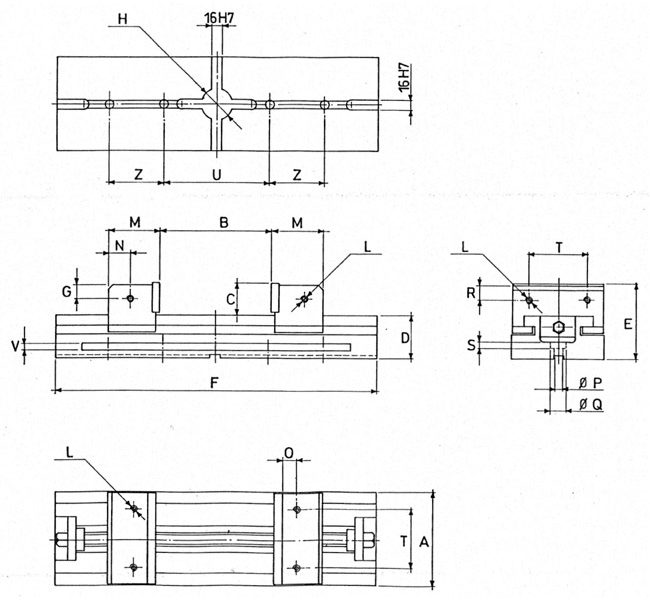

Technical data

Material: Cast iron GS 600-3 UNI 4544

Breaking Load: Rmin = 61

Elongation %: A% = 3

Brinnel hardness: HB = 190÷270

| TYPE | 100 | 125 | 150 | 175 | 200 | TOLL. |

|---|---|---|---|---|---|---|

| A | 100 | 125 | 150 | 175 | 200 | |

| B | 200 | 270 | 370 | 430 | 500 | +1,00/+5,00 |

| C | 47 | 52 | 52 | 57 | 57 | |

| D | 55 | 60 | 65 | 70 | 70 | ±0,02 |

| E | 102 | 112 | 117 | 127 | 127 | |

| F | 375 | 470 | 570 | 630 | 700 | |

| G | 25 | 25 | 25 | 25 | 25 | |

| H | 40 | 60 | 60 | 60 | 60 | H7 |

| L | M10 | M10 | M10 | M10 | M10 | |

| M | 86.5 | 98.5 | 98.5 | 98.5 | 98.5 | |

| N | 40 | 45 | 45 | 45 | 45 | |

| O | 25 | 25 | 25 | 25 | 25 | |

| P | ø16 | ø16 | ø16 | ø16 | ø16 | |

| Q | ø22 | ø22 | ø22 | ø22 | ø22 | |

| R | 25 | 25 | 25 | 25 | 25 | |

| S | 14.5 | 14.5 | 14.5 | 14.5 | 14.5 | |

| T | 80 | 100 | 110 | 135 | 160 | |

| U | 100 | 150 | 200 | 230 | 300 | |

| V | 10 | 10 | 10 | 10 | 10 | |

| Z | 75 | 75 | 100 | 100 | 100 | |

| WEIGHT KG | 15 | 24 | 36 | 51 | 68 |

Note: Features and dimensions are subject to change.

Related products

Request information

"*" indicates required fields